Qualification honor

In 2009, he was-We were the Shenzhen Science and Technology Innovation Award; in 2009, he was-We were approved as a national high-tech industrialization demonstration base, and the construction project was "XCF high-performance carbon fiber composite products"; in 2010, he was-We were recognized as a first-class enterprise for export industrial products by Shenzhen Inspection and Quarantine Bureau ; In 2017, it was recognized as the annual key enterprise and public institution of Shenzhen Guangming New District; in 2018, it was recognized as the "Guangdong Province High Modulus Carbon Fiber Composite Material Engineering Technology Research Center"; in 2018, it passed the "Enterprise Intellectual Property Management System Certification"; in 2018 It Passed gained the "National High-tech Enterprise" again; in 2019, it successfully passed the ISO09001: 2015 version upgrade certification; in 2021, it Passed-gained the customs AEO advanced certification.

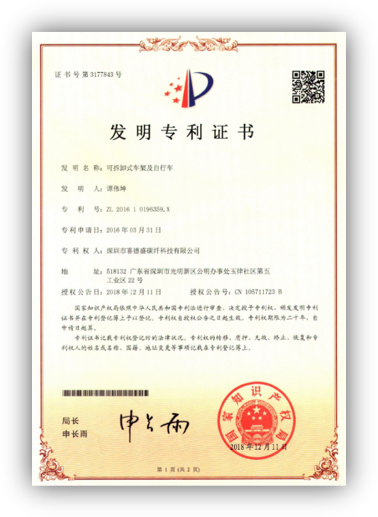

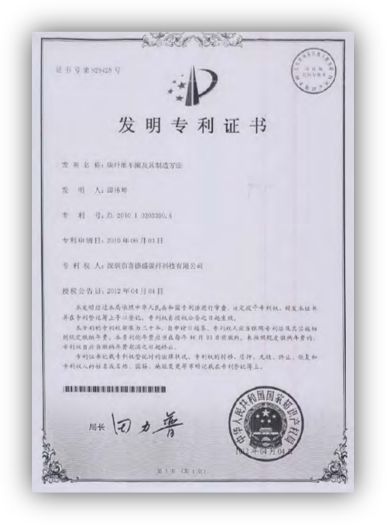

Related core technologies have applied for invention patents

| Serial number | patent name | type | Application Number/Authorization Number | Legal status |

|---|---|---|---|---|

| 01 | Carbon fiber rim and manufacturing method thereof | Patent | ZL201010203390.4 | Authorized |

| 02 | Detachable frame and bicycle | Patent | ZL201610196359.X | Authorized |

| 03 | Carbon fiber prepreg transfer method and carbon fiber prepreg product | Patent | CN202010654521.4 | Under review |

| 04 | Frame forming method and bicycle | Patent | CN202010679077.1 | Under review |

| 05 | Compression molding die and compression molding method | Patent | CN202010655767.3 | Under review |

| 06 | Carbon fiber prepreg and preparation method thereof | Patent | CN202010660603.X | Under review |

Related core technologies have applied for utility model patents

| Serial number | patent name | type | Application Number/Authorization Number | Legal status |

|---|---|---|---|---|

| 01 | Head tube core mold and carbon fiber composite products | Utility model patents | 202021211143.4 | Under review |

| 02 | Front fork assembly, body structure and riding vehicle | Utility model patents | 202021275050.8 | Under review |

| 03 | Mould and frame | Utility model patents | 202021295199.2 | Under review |

| 04 | Seat post mounting components, car body structure and cycling vehicles | Utility model patents | 202021274441.8 | Under review |

| 05 | Front fork assembly, body structure and riding vehicle | Utility model patents | 202021264507.5 | Under review |

| 06 | Frame fixture | Utility model patents | 202021334138.2 | Under review |

| 07 | Fork pipe fixture | Utility model patents | 202021330511.7 | Under review |

| 08 | Front fork assembly, body structure and riding vehicle | Utility model patents | 202021250534.7 | Under review |

| 09 | Front fork assembly, body structure and riding vehicle | Utility model patents | 202021264228.9 | Under review |

| 10 | Hidden cabling frame and bicycle | Utility model patents | 202021250533.2 | Under review |

| 11 | Moulds and cycling vehicles | Utility model patents | 202120027937.3 | Under review |

| 12 | Processing fixture, frame bottom bracket processing device and frame bottom bracket | Utility model patents | 202120037627.X | Under review |

| 13 | Processing fixture, frame down tube processing device and frame down tube | Utility model patents | 202120028047.4 | Under review |

| 14 | Fixed workpiece assembly jig and fixed workpiece assembly device | Utility model patents | 202120041473.1 | Under review |

| 15 | Coil table | Utility model patents | 202120037895.1 | Under review |

| 16 | Mandrel and verification components | Utility model patents | 202120044239.3 | Under review |

High-precision CNC machining workshopIndustry-leading CNC workshop

The company has complete supporting production equipment. There are coating machines, unidirectional fiber prepreg machines, frame testing machines, paint spraying stations, vertical machining centers, fatigue testing machines, CNC drilling and tapping centers, high-speed precision machining centers, three-coordinate measuring machines, five-axis Machining center machine, microcomputer wheel set deflection testing machine, vertical machining center machine, impact testing machine, east frame polishing and dust collection system, BK high-precision cutting machine, Demi drilling and milling machining center machine, CNC two-component mixed dispensing Machine, CNC cutting machine, automatic cutting machine, variable frequency screw air compressor, automatic paint spraying machine, HS-3 001A universal material testing machine, front fork static testing machine, three-axis CNC profiling machine, three-axis single-head CNC simulation Shaping machine, oil-injected screw air compressor, PU low-pressure mixing perfusion machine, CNC lathe, etc.

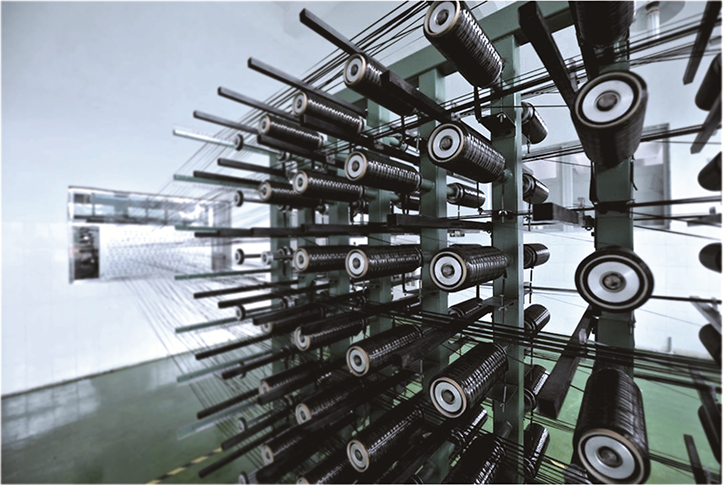

The world's largest carbon fiber factory Modern yarn weaving workshop

As the world's largest carbon fiber factory, the company has reached the international leading level in carbon fiber composite molding technology and application, with first-class hardware equipment, excellent technical personnel and advanced management methods, and product performance has reached the international leading level.

New product RS800 Two-mold integrated molding process design

Integrating nanotechnology and dual-mold integrated molding process, using internal and external dual molds to create a hollow integrated carbon fiber frame, the frame is integrated into a triangle, and the inner wall and appearance of the frame are extremely smooth, preventing the carbon fiber material from being caused by uneven surfaces The performance of the vehicle is compromised, and there is no adhesion between the structures, and the components are precision-linked with zero error. The frame structure forms a stable whole. While having the characteristics of ultra-lightweight and ultra-high rigidity, it stimulates the strongest performance of the frame, and the performance is far Super level!